COB technology has excellent performance and is positioned in the high-end commercial license market. Compared with SMD LED, COB has the following advantages:

1. High packaging efficiency and cost saving

The COB packaging process is not much different from the SMD production process, but the packaging efficiency of COB packaging in dispensing, separation, spectroscopy and packaging is much higher. Compared with discrete LED devices, COB light source modules can save the cost of primary packaging of LEDs, the production cost of light engine modules and the cost of secondary light distribution in applications.

2. Low thermal resistance advantage

The system thermal resistance structure of SMD package is chip-die glue-solder joint-solder paste-copper foil-insulation layer-aluminum, while the system thermal resistance of COB package is chip-die glue-aluminum. The system thermal resistance of the COB package is much lower than that of the traditional SMD package, so the LED lamps in the COB package have a longer service life.

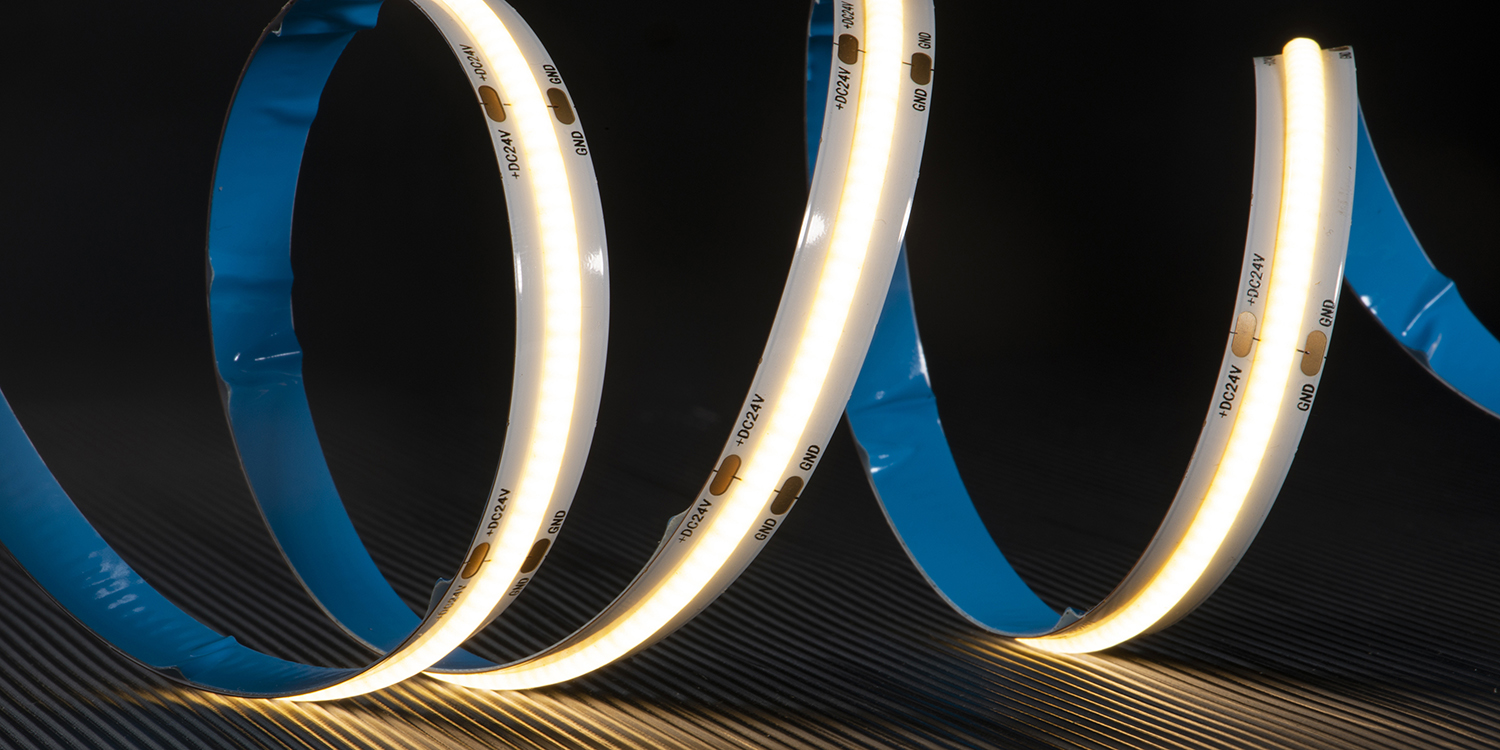

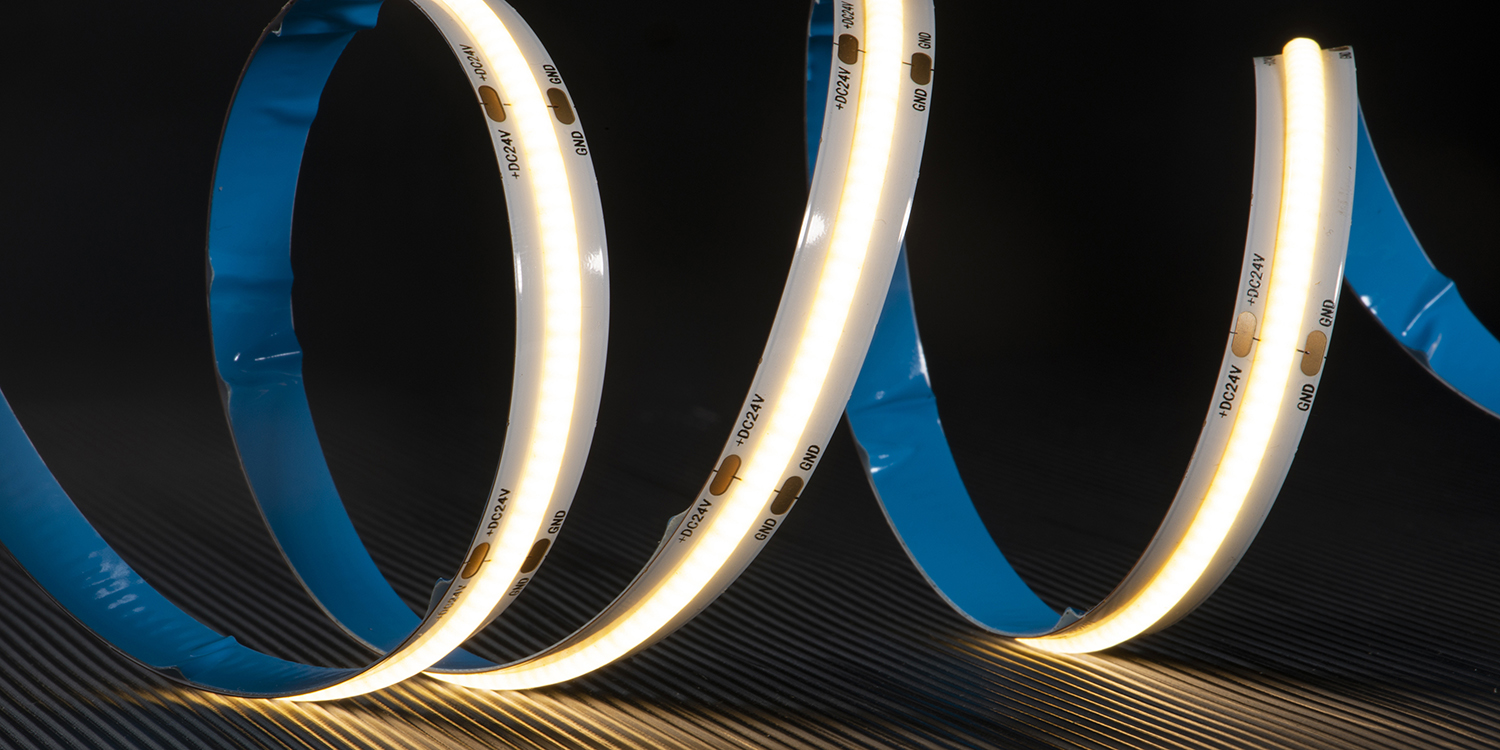

3. Light quality advantage

The SMD package attaches multiple discrete devices to the PCB board in the form of patches to form a light source component for LED applications. This approach has problems of spot light, glare and ghosting. Since the COB package is an integrated package and is a surface light source, the viewing angle is large and easy to adjust, which can reduce the loss of light refraction.

4. Application advantages

The application of COB light source is very convenient, and it can be directly applied to lamps without other processes. The traditional SMD package light source also needs to be patched first, and then fixed on the PCB board by reflow soldering. It is not as convenient as COB in application.

The COB device emits a surface light source, which makes it easier to achieve the consistency of light color and achieve high-quality spot effects. Therefore, COB devices have been used in high-demand lighting places, such as high-end hotels, high-end retail stores or museums and other high-end commercial lighting markets.